iMicrobes produces 100% bio-based acrylic acid through its scaled-up bioprocess

ALAMEDA, CA – September 9, 2025 – Industrial Microbes (iMicrobes), a pioneer in industrial biotech, today announced a major breakthrough in sustainable chemical manufacturing: the successful scaled production of 100% bio-based, high-purity acrylic acid through advanced fermentation technology.

With backing from BioMADE, the achievement represents a significant step toward decarbonizing one of the chemical industry's most ubiquitous materials.

"This project is a great example of how U.S. bioindustrial manufacturing can deliver critical materials without relying on foreign inputs," said Ashley Arnell, Technology Program Manager at BioMADE.

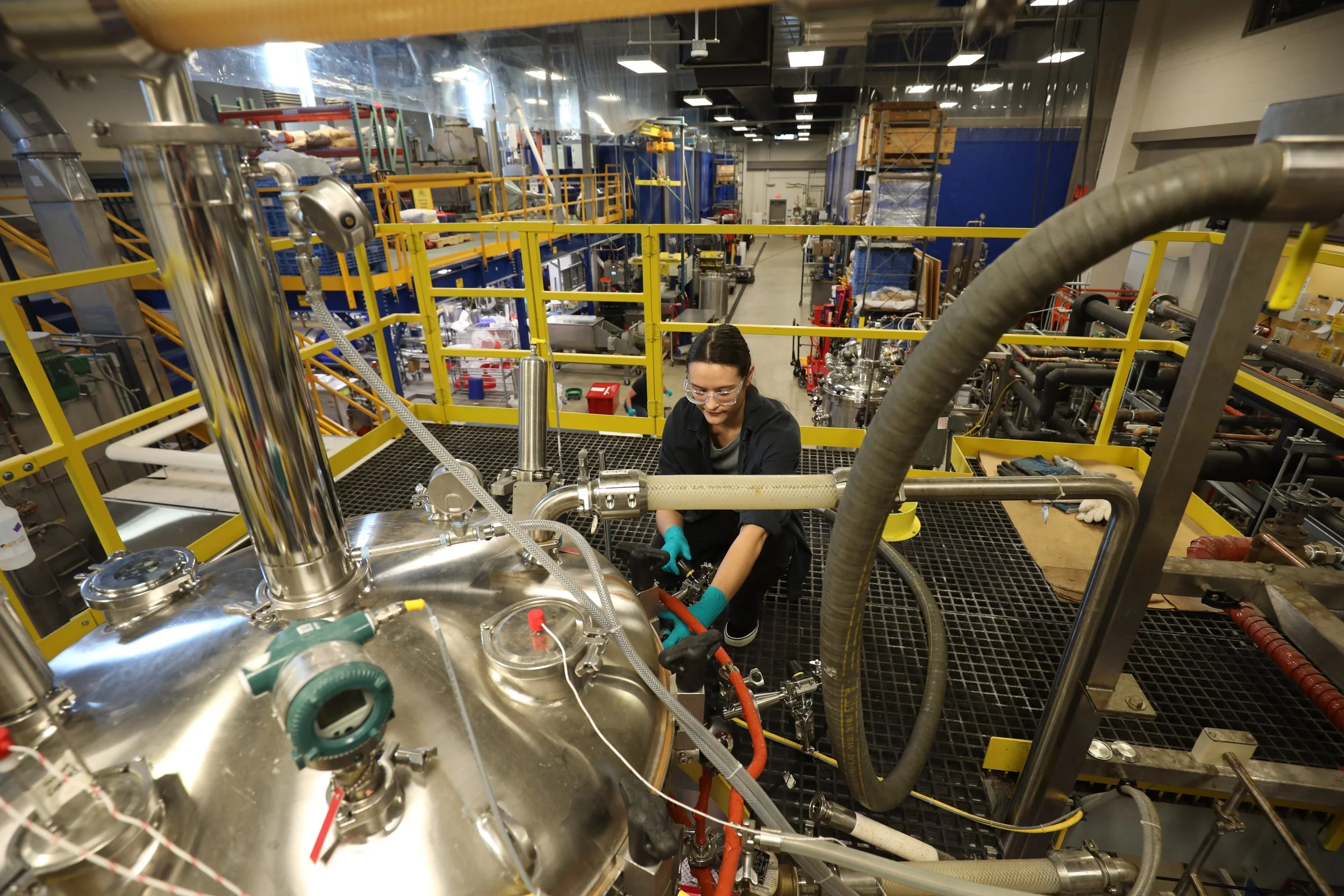

Scaled-up manufacturing of iMicrobes bio-based acrylic acid at IBRL. Credit: Taylor Meredith.

“By scaling this process, they are not only advancing the production of bio-based acrylic acid, but also strengthening domestic supply chains for high-value chemicals.”

Acrylic acid is essential to hundreds of applications across consumer goods, industrial, and defense sectors, from the paints on our walls and adhesives for electronics and military optics to super absorbent polymer (SAP) for diapers, and the market is projected to reach $18 billion by 2030.

From lab to market: proving scale and economics

In collaboration with the Integrated Bioprocessing Research Lab (IBRL), iMicrobes has rapidly scaled its proprietary bioprocess from gram-scale to 20-kilogram production batches, while expanding fermenter volume from 2-liter to 1,500-liter reactors.

This dramatic 750x increase demonstrates the technology's scalability for commercial deployment.

"We've developed an elegant bioprocess that can make bio-based chemicals economically competitive with petrochemicals," said Noah Helman, CEO and co-founder of iMicrobes. "By engineering our process with cost as an uncompromising design constraint, we've built a solution that can compete on economics and produce net-zero materials. We're grateful for BioMADE's support in helping us scale this technology and demonstrate its commercial potential."

100% bio-based acrylic acid. Credit: iMicrobes.

“By engineering our process with cost as an uncompromising design constraint, we’ve built a solution that can compete on economics and produce net-zero materials.”

The company's breakthrough lies in its streamlined production approach. Using ethanol as a renewable feedstock and its proprietary engineered microorganisms, the iMicrobes bioprocess combines multiple chemical reactions in a single reactor at mild temperatures.

Their innovative purification method eliminates toxic solvents and complex extraction steps, allowing for a potential cost advantage compared to traditional methods.

Biobased carbon fiber is on deck

The iMicrobes platform technology extends beyond acrylic acid to other related chemicals including acrylonitrile, which is used to make strong and lightweight carbon fiber. The acrylonitrile method leverages the same bioprocess coupled with a different downstream chemical reaction, accelerating the product development cycle and shortening the time-to-market for bio-acrylonitrile.

This positions iMicrobes at the center of the advanced materials revolution of domestic biomanufacturing, which is critical as the United States currently imports nearly half of its carbon fiber.

Commercial traction validates market demand

The economic advantages are already resonating with industry partners. iMicrobes has secured multiple Letters of Intent from commercial partners across the value chain and is actively exploring additional partnerships.

"The chemical industry, as well as consumer brands, are hungry for bio-based, drop-in solutions that don't compromise on performance or economics," added Helman.

“Our partners see our products as a competitive advantage and a strategic move to meet their net-zero goals while capturing the fast-growing sustainable market segment.”

Credit: World Bio Markets.

About Industrial Microbes

Founded by a team of biotechnology and biomanufacturing experts, Industrial Microbes (iMicrobes) is pioneering cost-competitive, sustainable materials through advanced synthetic biology. The company’s patented microbial strain engineering and precision fermentation technologies convert next-generation feedstocks into drop-in chemicals for a wide range of industrial applications.

With a portfolio of 23 patents, iMicrobes is building the next generation of biomanufacturing, enabling chemical companies to reduce reliance on fossil-based inputs while maintaining performance and scalability.