How to design a biomanufacturing process for success

By Noah Helman, Founder and CEO, iMicrobes

5-minute read

Imagine two parents with a baby stroller standing in the supermarket aisle, faced with a decision: two identical boxes of diapers – same brand, same performance, same price – except one is in green packaging. Looking closer, they realize one kind is made from petroleum while those in the green box are made from biobased, renewable resources and with zero carbon emissions in its manufacturing life cycle. They double-check the prices – still equal. Which do you think they buy?

Most people I’ve talked to want to buy the greener product, they just don’t want to pay more for it. In fact, 78% of consumers consider environmental sustainability important, and aspire to lead more sustainable lives, which is why sustainable products are growing at a rate 2.7 times faster than non-sustainable products. While some people are willing to pay more, it’s clear that green products will take over the larger market when they are the same price or lower.

For decades, we have relied on the oil and petrochemical industries for affordable useful products that make our lives convenient and comfortable. But we are traveling down an unsustainable path. The good news is that renewable technologies are being deployed in ever-increasing quantities to fulfill our energy needs, led by the low cost of solar panels, wind turbines, and batteries. In the chemical industry, we should learn from their experience, and we should take advantage of these energy sources as we rethink how to make chemicals more sustainable.

Advances in biomanufacturing have offered alternatives to traditional fossil fuel-derived chemicals. Many visionary companies have invested brainpower, years of research, and millions of dollars to bring biobased chemicals to market, exploring a variety of technical approaches and business strategies. Some have succeeded and others have failed – what differentiates the best approaches from those that haven’t gotten to market?

Industry veterans, like me and our team at iMicrobes, have learned that cost-competitiveness is the key to accelerating this transformation. We're actively shaping biomanufacturing processes to achieve reliability, scalability, and crucially, price parity with petroleum-based incumbents. To avoid the pitfalls of the past, we have studied these historical examples. Here’s what we found.

Why some biomanufacturing processes thrive—and others fail

Everyone knows that biomanufactured medicines can create successful businesses, largely because of their incredible pricing power. Most people doubt that bulk chemicals can compete in the market when you have to achieve very large scale production and hit low price points–but that’s not actually true. There are proven examples of large-scale fermentation-based products in the market in the $1500/MT - $3000/MT range today. The promise of using industrial biotechnology for environmentally-friendly chemical manufacturing is clear. But why have some projects thrived while others faltered? Success hinges on two critical factors:

Feedstock economics: Choosing feedstocks carefully to optimize cost-per-output is key. Expensive inputs or low-yield processes quickly erode profitability.

Efficient purification: Streamlined downstream processing dramatically reduces operational costs. Complex, costly purification can doom even promising innovations.

Successful examples include amino acids (e.g. lysine and threonine for animal nutrition, glutamate for food flavoring) and biochemicals, such as butanediol (like Geno BDOTM) and propanediol (e.g. Sorona carpet fibers from Covation Bio).

Image credit: Evonik

These examples illustrate the viability of fermentation at industrial scale—when feedstock and purification costs are carefully managed. For example, lysine is sold today in the US at prices that top out at about $2000/MT. Bulk lysine can be biomanufactured profitably at that price because the fermentation efficiency is close to its maximum theoretical yield, and the product is purified from the broth using a limited number of well-established unit operations including membranes, ion exchange, and evaporation in a cost-effective process.

The lesson is that controlling costs in the industrial biotechnology industry depends on the design choices we make that enable simplified downstream separations and purification.

iMicrobes strategy: An economically viable pathway for acrylic acid

From the start, we designed our biomanufacturing approach with these lessons in mind. Our focus is not on incremental improvements but a transformative process engineered explicitly for cost competitiveness. We identified ethanol as our feedstock—not because it is lower cost per ton than traditional sugars (dextrose), but because the exceptionally high product yield from this feedstock translates to significantly lower overall costs per ton of product.

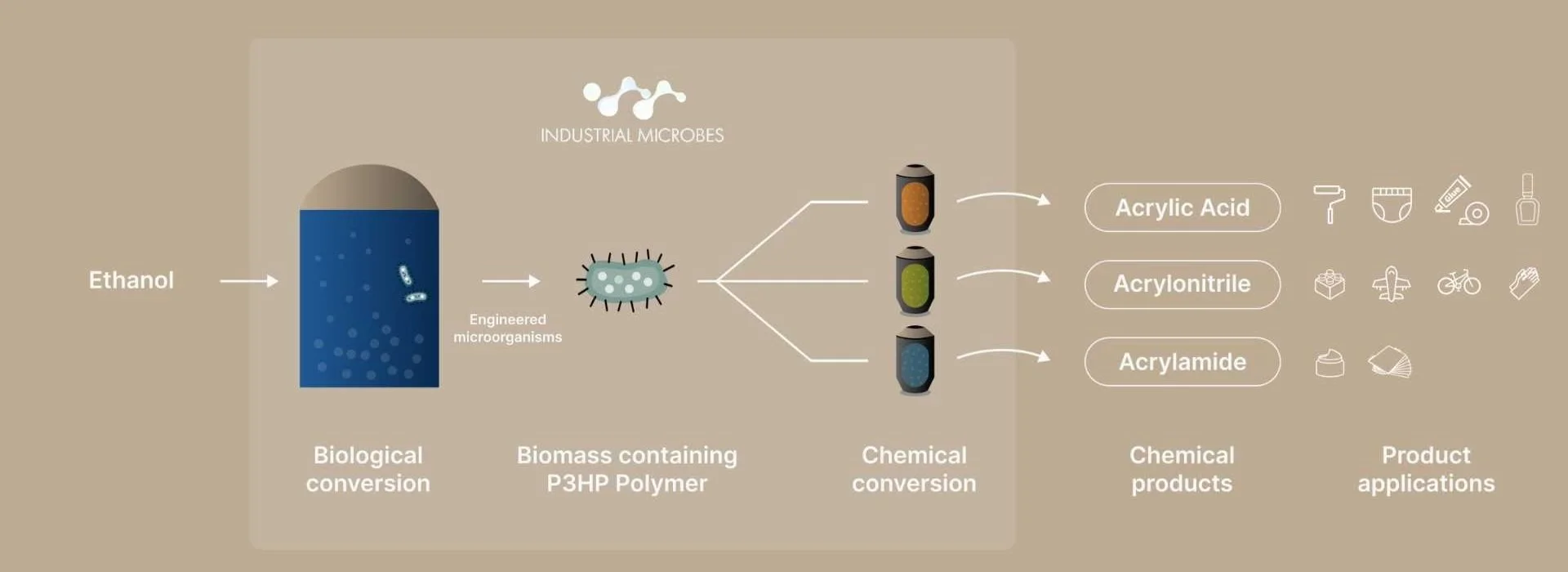

We also chose to produce a unique intermediate product: poly-3-hydroxypropionate (P3HP). Unlike traditional intermediates like 3-hydroxypropionic acid (3HP), P3HP is stable, non-toxic, and easily accumulates within our engineered microbes at extremely high concentrations (up to 90% of total dry weight). This choice radically simplifies purification: we remove cells containing the product by simple centrifugation, dry the biomass and product together, and heat it to yield high-purity acrylic acid vapors. Using standard chemical unit operations including distillation, we achieve product purity efficiently and inexpensively.

iMicrobes biomanufacturing process

Why not go directly to acrylic acid or soluble intermediates like 3HP? Both 3HP and acrylic acid are reactive, can be toxic to microbes (especially acrylic acid), and are expensive to purify at commercial scale. Our polymer-based intermediate neatly sidesteps these problems, simplifying downstream processing and dramatically cutting purification costs.

Bringing biotechnology to commodity chemicals: Lessons from experience

The pitfalls of past biotechnology efforts underline the importance of strategic design choices. Our founding team learned firsthand at LS9 how promising technologies falter when they can’t win on economics. Cost competitiveness isn’t just beneficial—it’s essential.

Our techno-economic modeling approach confirmed that our P3HP process fulfills crucial criteria for success:

Cost competitiveness: Matches or beats current petrochemical costs

Carbon efficiency: Significantly reduces emissions and provides a net-zero pathway

Technical feasibility: Proven biological and chemical methods combined strategically

Feedstock flexibility: Ethanol availability and future carbon-negative potential from waste-derived and recycled sources

Initial market adoption and strategic scale-up

While cost parity is our ultimate goal, initial market entry can leverage targeted green premiums, carbon credits, and strategic government support. Forward-thinking early adopters play a vital role in bringing new sustainable materials to market, validating demand, and refining scale-up processes.

Our initial scale-up clearly has demonstrated technical feasibility. Already, we’ve achieved fermentations at 1,500 liters, delivering tens of kilograms of polymer. This proof of concept lays the groundwork for full commercialization.

Credit: iMicrobes

Government investment and incentives, such as recently announced awards, enhance our economic proposition. Early adopters that secure supply soon can both demonstrate sustainability leadership and futureproof their supply chains with valuable differentiated products.

A cost-driven future for industrial biomanufacturing

Our biomanufacturing process isn’t only promising in theory—it’s designed from first principles to succeed economically. Our approach integrates proven techniques from biology and chemistry to deliver an affordable, sustainable alternative to petroleum-derived acrylic acid.

Commodity chemical markets demand scale, performance, and, above all, cost parity. At iMicrobes, we’ve built our business around these requirements, confident that this strategic approach positions us—and our partners—for long-term success. The opportunity to reshape industrial chemicals sustainably and profitably has arrived, and we’re ready. With a 60% cost reduction since early 2024, iMicrobes is rapidly advancing toward cost-competitive, scalable biomanufacturing solutions.