A circular economy needs products built from waste

Written by Noah Helman, PhD, CEO.

The latest SynBioBeta conference in Oakland brought together hundreds of the world’s synthetic biology leaders. I had the privilege to get on their main stage to present our thoughts on why "A circular economy needs products built from waste".

Check out the video:

Here is the transcript of the session:

At Industrial Microbes, our focus is on the circular economy, which involves finding ways to take waste products and convert them back into raw materials for manufacturing everyday products.

Specifically, we are dedicated to using methane as the material for recycling carbon, which can be transformed into various products. Methane is a potent greenhouse gas, about 86 times more damaging than carbon dioxide for global warming. By repurposing methane as a raw material, we can reduce its harmful impact on the environment and utilize it to make chemicals and materials.

Methane can be sourced from various biogenic sources such as wastewater treatment, landfills, and organic waste, like animal waste.

Our team at Industrial Microbes is working on engineering strains of bacteria capable of turning methane into a wide range of chemicals. This not only prevents methane from being released into the atmosphere but also provides a low-cost feedstock for producing essential chemicals used across different industries.

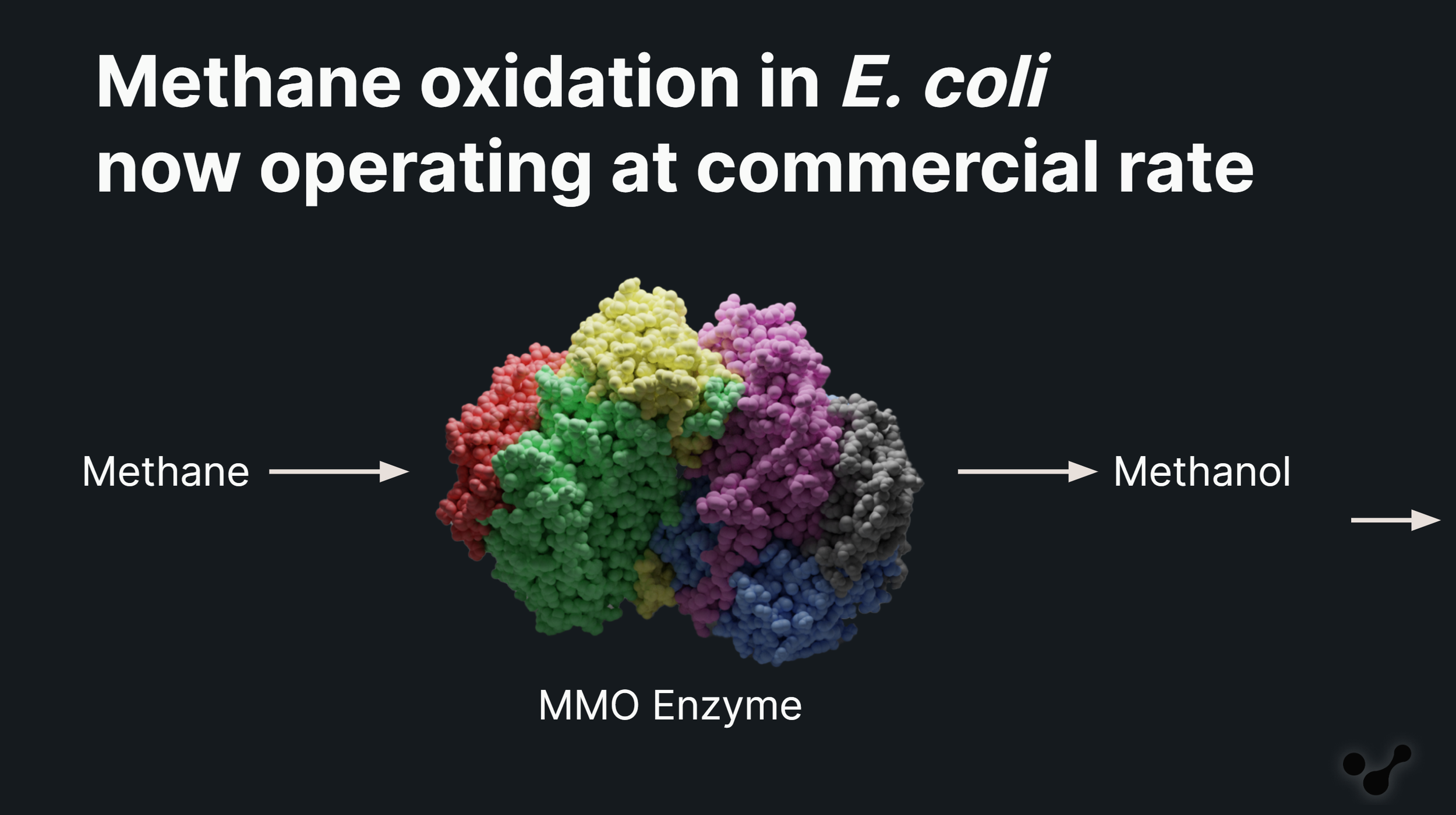

Scientifically, our breakthrough came when we developed a technique to turn E. coli bacteria into a synthetic methanotroph. This modified strain can consume methane as a raw material. Initially, experts in the field discouraged us, stating that such a conversion had been attempted for years without success. However, through the brilliant work of my co-founder and CTO, Liz Clarke, we succeeded in making it work. Now, we can use E. coli to convert methane into methanol, which can be further transformed into various complex products.

Currently, we have the capability to produce a variety of different products, including acrylic acid, which finds applications in diapers, paints, coatings, adhesives, and cosmetics.

Additionally, we are working on producing methacrylates used for making materials like acrylic glass (Plexiglas) and acrylonitrile, used in carbon fiber and synthetic rubber production. These materials are vital for lightweight vehicles and for creating hard plastics.

The circular economy approach opens up opportunities to remake many products that surround us. To achieve this, we must change the way we manufacture various chemicals and materials, starting from the waste materials in our society. A key aspect of this transformation is ensuring cost-competitiveness, and to that end, we have conducted a thorough techno-economic analysis to determine the feasibility of using methane as a feedstock for the chemicals and materials industry.

In conclusion, at Industrial Microbes, we are committed to contributing to a more sustainable future by harnessing the potential of the circular economy. By recycling methane into valuable raw materials, we can reduce greenhouse gas emissions and create a positive impact on the environment and our economy. Together, we can make a significant difference in building a greener and more responsible world.

Loved or hated this post? Tell Noah at hello@imicrobes.com.

About us

Industrial Microbes is developing carbon-negative materials to enable the transition to a circular economy and to reduce the carbon footprint of the chemical industry. We build microorganisms that make chemicals and materials from methane, a greenhouse gas 81x as potent as CO2. Our team has been working to decarbonize chemical production for decades and this series of articles will share our perspective on the massive changes we see coming.